Lignite: A New and Dedicated Approach

Proven and readily available technologies – bubbling fluidised bed combustion (BFBC) combined with a lignite agglomeration and drying system – can achieve a substantial efficiency improvement and consequent greenhouse gas emissions reduction

.

Dr. Michael C. Clarke, CPEng, FIEAust, FAusIMM, RPEQ

CEO, M.E.T.T.S. Pty. Ltd.

Consulting Engineers, Resource Management and Infrastructure Development

Gold Coast, QLD, Australia

Email: metts[at]metts.com.au

Originally published in: Energy Generation, October/December 2010, pp 40 – 41.

INTRODUCTION

For over 80 years Victoria has sourced most of its electricity from lignite resources located in the Latrobe Valley. This lignite has provided Victoria (and Australia) with much of the energy that has created the present First World economy that we all share. The energy (electricity) has been cheap and very reliable.

The major changes in ownership of the power generation infrastructure, along with mooted changes in the carbon costs associated with utilisation of the lignite resource, have created uncertainty in the future of lignite-fuelled power generation. The result has been a near cessation of investment in new lignite-fuelled power generation infrastructure and/or the undertaking of major maintenance to existing power stations. To maintain the reliability of electricity supply in south-eastern Australia, new power generation plant is required and lignite can play a role.

The power generation plant presented in this proposal has an energy conversion efficiency greater than 38%, which is around a 10% improvement on existing plant performance. Proven and readily available technologies will be used in the plant to achieve this substantial efficiency improvement and consequent greenhouse gas emissions reduction. Bubbling fluidised bed combustion (BFBC) combined with a lignite agglomeration and drying system is the suggested technology. The plant design will enable the future addition of carbon capture and storage (CCS) equipment and co-firing with biomass.

TECHNOLOGY CONSIDERATIONS, FUEL AND SYNERGIES

Bubbling fluidised bed combustion is a well accepted technology in China where it is used for small- to medium-scale power generation and the provision of industrial heat. BFBC plants are often built on a scale of between 25 and 100 MWe and therefore suit modular construction and operation. They are also excellent plants for utilising high volatile fuels with low ash that quickly disintegrate when exposed to flame and abrasion.

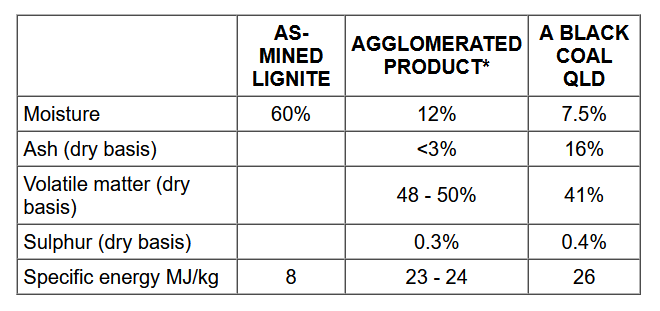

The agglomerated product produced from Victorian lignite will vary in quality according to the input feed, but a general composition is shown in Table 1. For comparison, the composition of a medium-quality, black thermal coal with very low ash and very low sulphur is also shown. The specific energy of the comparison coals is shown in Figure 1. It is notable that the black coal and agglomerated lignite product have similar characteristics.

Table 1 - Raw Victorian lignite and processed product compositions

* From information supplied by White Energy and Environmentally Clean Technologies - Coldry

The BFBC plant’s superior combustion performance will be assured by the very high volatile content, low-to-medium moisture content, and very low ash of the processed fuel product. The low ash will prevent occlusion of combustibles during combustion, while the small sulphur content will be absorbed by limestone sorbent added to the fluidised beds or incorporated in the fuel.

The water extracted from the raw, as-mined lignite, can be utilised in the cooling system of the new power plants, or be offered to Victoria (Melbourne) as an immediate supply of industrial water or, with minimal processing, as a potable water. The low ash content will result in limited ash being produced by the power generation plants with that ash being returned as fill to the mining pits or possibly used in the manufacture of building materials.

The use of agglomerated, dry lignite product in BFBC power generation units can be designed to have a significantly reduced environmental impact compared to existing generation plant. Emissions of sulphur will be minimal, acidic nitrogen oxides will not be created in a low-temperature combustion system, and the total system efficiency will be compatible with or better than other existing thermal Australian power stations. A basic schematic for the concept is shown in Figure 2.

Figure 1. Comparative steaming coal properties

'COAL' TO POWER

The combustion of fuels to release heat, then using that heat to run a steam cycle for power generation is not new; in fact it has been around for some 130 years in various forms. The most widely used system for raising steam for major power generation is pulverised fuel (PF) firing, a system that has been applied to coals ranging from lignite (as in Victoria), through the bituminous range (as in New South Wales and Queensland) to anthracite (as in Vietnam and the USA). It has proved versatile and reliable and will continue to be the conversion process of choice for many new coal-fired power stations.

The combustion characteristics of specific coals or coal products should be taken into account when considering what is the most appropriate conversion technology. Pulverised fuel firing requires coal to be presented to the combustor in a very finely ground state, with particle size distribution commonly having greater than 70% passing 75 microns. This grinding requirement has a monetary cost for power, plant and materials, and is expensive for coals with low Hardgrove Index numbers, say less than 40, as occur in Queensland’s high volatile, bituminous coals. Coals that have low volatile matter require grinding to a fine state simply to allow the aggregated particle surface area to be great enough to provide acceptable char burnout rates. Coal combustion scenarios are shown in Figure 3.

Figure 3. Coal combustion processes (After: Zhangfa Wu, IEA Clean Coal Centre, 2005)

Combustion system A occurs for volatile coals combusted in PF (and other combustion systems). Where coal has little or no volatile matter, the combustion system C will predominate. In this system coal-char gradually combusts; however for high mineral matter fuels low rates of char burnout are likely. If this is the case circulating fluidised bed combustion (CFBC) with high recycle of fuel should be considered, as the continuously forming occluding ash on char particles will be abraded off the particles opening new surfaces for combustion.

For coals and coal products with high volatile content and low mineral matter, BFBC should be considered. The combustion system would look like system B in Figure 3 above. The coal particles or agglomerates would be subject to rapid fracturing through thermal shock and volatiles expulsion, as well as particle size reduction through abrasion and scaling, and further fragmentation through particle collision in the bed and freeboard.

It can be noted that if high recycle of partially burnt fuel is not required with high volatile and low mineral matter fuels to achieve very high carbon burnout, the use of BFBC should be preferred to the use of more complex and more expensive PF and CFBC technologies.

OXY-FIRING COAL-FIRED POWER GENERATION

In recent times PF combustion units have been considered for conversion (retrofitting) to oxy-firing, where oxygen diluted with flue gas replaces air as the oxidising agent. The BFBC units could also be operated in oxy-fuel mode, thus producing a concentrated carbon dioxide waste product stream for sequestration post combustion. The general scheme is shown in Figure 4 below.

Figure 4. Oxy-fuel firing of a bubbling fluidised bed combustor power station

BUBBLING FLUIDISED BED COMBUSTOR

Coal sulphur is captured in the combustor using limestone sorbent, in a minimum ratio of two moles of calcium to each mole of sulphur. Limestone could be added to the fuel at the point of pellet or briquette manufacture. For the Victorian lignites, the limestone content of the fuel would be between 0·6% and 1% dry basis.

Ash removal from the combustor will be primarily at the base of the boiler, but some provision for ash removal under the combustor should be made. The flue gas cleaning system will consist of jacketed cyclones followed by an electrostatic precipitator (ESP) – Figure 4.

Ash utilisation should be investigated as resource recovery and carbon abatement opportunities. The manufacture of non-fired building materials may be an option.

Figure 5. A bubbling fluidised bed combustor system

FUNCTION OF THE RECYCLED FLUE GAS

The recycled flue gas has three functions in the BFBC system. These are:

• As a fluidising gas with a velocity of 0·5 – 2 m/s [Given the low ash content of the proposed fuel, its low density and its likely propensity to thermally disintegrate (Figure 3, cases A and B), fluidising velocities in the range of 0·5 – 1 m/s may be most appropriate.]

• Ensuring that there are even temperatures in the combustor, especially in the bed (to avoid hot spots and bed sintering) and the freeboard, and

• Being a carrier of (conductive) heat to ensure efficient heat transfer to all heat exchange–boiler surfaces.

BED MATERIAL

Coarse, washed sand is a traditional bed material in BFBC units. It is a consumable and needs to be constantly topped up from time to time. Sand can be supplemented or replaced with crushed and sized limestone for sulphur control. Note: If limestone was used as the bed material, then limestone addition to the fuel could be dispensed with. Some test-work may be required with specific bed materials and coal ash to examine if sintering is likely with the temperatures that will be produced by oxy-firing over a range of oxygen to flue gas ratios.

SPECIFIC PLANT PERFORMANCE SPECIFICATIONS

i. The ‘coal’ would be a high volatile (45–50% VM), pelletised or briquetted Victorian lignite with a moisture content of 12% or less.

ii. The specific energy of the fuel will be around 22–24 MJ/kg.

iii. The ash will be less than 5% (dry basis) inclusive of limestone if required, and the burnout will be greater than 99%.

iv. Carbon dioxide separation and capture will be a greater than 90%.

v. The oxygen content of the fluidising gas could be around 30% (this needs to be confirmed with modelling).

vi. The excess oxygen in the flue gas should be low (given the low ash and high volatility of the fuel) and be less than 4%.

vii. Process start-up will be with air and natural gas, with the phasing in of flue gas supplemented with oxygen as the solid fuel begins to combust.

viii. The air separation unit will probably be cryogenic but could be membrane and will produce an oxygen stream of greater than 90% purity.

PLANT EFFICIENCY TARGETS

The existing Victorian lignite-fuelled power stations are reported to have thermal conversion efficiencies of less than 30%. The Commonwealth Government, through the Australian Greenhouse Office (AGO), is looking to improve the efficiency of fossil fuel power generation and thus reduce the carbon footprint of such generation in the future. They have set minimal performance standards for new plant at:

• Natural gas plant – 52% thermal efficiency, net sent-out (nSO) higher heating value (HHV),

• Black coal plant – 42% nSO (HHV), and

• Brown (lignite) coal plant – 31% nSO (HHV).

Reaching or surpassing the net sent-out efficiency of natural gas and black coal plants as proposed by the AGO with future advanced lignite-fuelled generation is considered unlikely, but increasing the plant efficiencies into the high 30s with suitable fuel preparation and using high-efficiency fluidised bed combustion units is possible.

To meet such targets as 34–36% efficiency, advantage must be taken of the very high heat release rates that are possible with the combustion of processed high volatile, low ash lignite with moisture contents of around 12% and specific energy of around 24 MJ/kg with high efficiency combustor heat transfer.

A PROCESS CHALLENGE

Ash fusion temperatures (AFTs) as low as 1160ºC (initial deformation in a reducing atmosphere) have been reported for some Victorian lignite ash. Industry experience has indicated that care must be taken with AFTs to avoid boiler fouling in the existing boilers, with avoidance through lignite blending and combustor temperature monitoring and adjustment. This care will need to be maintained with the use of BFBC systems. Ensuring that the AFT (ID) of fuel feed is greater than 1200ºC is an excellent start.

FUEL PROCESSING AND UPGRADING

The Victorian lignites are‘young’ lignite, with an exceptionally high moisture content, generally around 60%. However, they have low ash and low sulphur. Two processes, binderless briquetting (commercialised by White Energy) and pelletisation (developed by ECT, ‘Coldry’) have the potential to reduce the moisture to around 12%, with a specific energy between 23 and 24 MJ/kg. The ash in the processed product would be around 3–4%, and sulphur around 0.3%.

Given that the two processes produce a product of similar qualities, the choice of process will be largely dependent on their cost of fuel at the power station gate, the readiness for process rollout and the quality of the water by-product.

TOWARDS HAVING A CCS READY SYSTEM

The definition proposed by the International Energy Agency states that, ‘a plant may be considered capture-ready when CO2 capture can be included when the necessary regulatory or economic drivers are in place. The definition requires the project developer to demonstrate that factors in their control that would prevent the retrofit of CO2 capture have been identified and eliminated. Specific aspects that must be considered include:

• A study of options for CO2 capture retrofit and potential pre-investments,

• Inclusion of sufficient space and access for additional facilities, and

• Identification of reasonable route(s) to the storage of carbon dioxide.’

In the IEA definition, the availability and suitability of carbon geosequestration sinks is not specifically mentioned, but is clearly a required prerequisite to a viable CCS power project.

In the Victorian situation, studies of options for new plant have, are, and will be undertaken to get a good understanding of all the components required for a Victorian lignite-based CCS project. Studies to date have concluded that the Bass Strait oil and gas fields will offer sufficient storage space as the fields are depleted.

PENALTY FOR CCS INCORPORATION

For a project over 600 MWe and with good CO2 route logistics and storage options, industry studies indicate that an efficiency penalty of around 30% will occur over a similar non-CCS plant. This would bring the efficiency back to around 24% nSO (HHV). This is a couple of percentage points below the ‘worst’ operating, lignite-fuelled Victorian power station.

The question now is, ‘would such an efficiency reduction penalty be acceptable to power station owners and operators and government regulators, and the community that will eventually have to pay for this reduction in higher electricity bills?’

CONCLUSION

Victoria, and indeed south-eastern Australia, has very substantial lignite resources. These resources have been powering industry, commerce and domestic demand for around 80 years. The efficiency of the energy conversion systems has been limited by the high moisture content of the raw fuel and the design of the combustor/boilers.

The use of fluidised bed technology to convert solid fossil fuels into electricity is well understood. The technology provides a ‘clean’ solution to SOX, NOX and ROX emissions, and given the increase in the conversion efficiency of lignite into usable energy, significantly lower carbon dioxide emissions per megawatt-hour than what is current practice.

The technology could be designed to be ‘carbon capture ready’ through the addition of oxy-firing and carbon capture systems. The operation of the new technology with carbon capture will however come at a significant efficiency cost, and thus a significant cost to the wholesale cost of electricity.

NOTE:

You are welcome to quote up to a maximum of three paragraphs from the above white paper, on condition that you include attribution to this website, as follows:

SOURCE: M.E.T.T.S. Pty. Ltd. Website https://www.metts.com.au